Products offered

ATON MOS

(purification and oxidation of post-process gases and removal of odours)

- MOS (Microwave Oxidation Treatment) is a technology for post-process gas after burning. It finds a wide field of applications in the area of neutralising harmful gas pollutants and odours and neutralising dust and exhaust stack particulates.

The technology is easy to implement and economically adapt for many business sectors.

Used, among others, in the chemical, food, recycling, mining, petrochemical, health, environmental, sustainability and climate mitigation sectors.

ATON HR

(neutralisation of petroleum pollutants)

- ATON HR devices perfectly neutralise harmful compounds in a concentrated microwave field in an oxidising atmosphere.

- The ATON process is controlled remotely on three basic parameters (temperature, quantity and quality of the atmosphere supplied), all adjusted to the recipients’ needs.

- When used in a cleanup of a petroleum spill on sand and soil after cleaning, the carrier materials can be reused as sand and soil once more without posing any risk to people and the

environment.

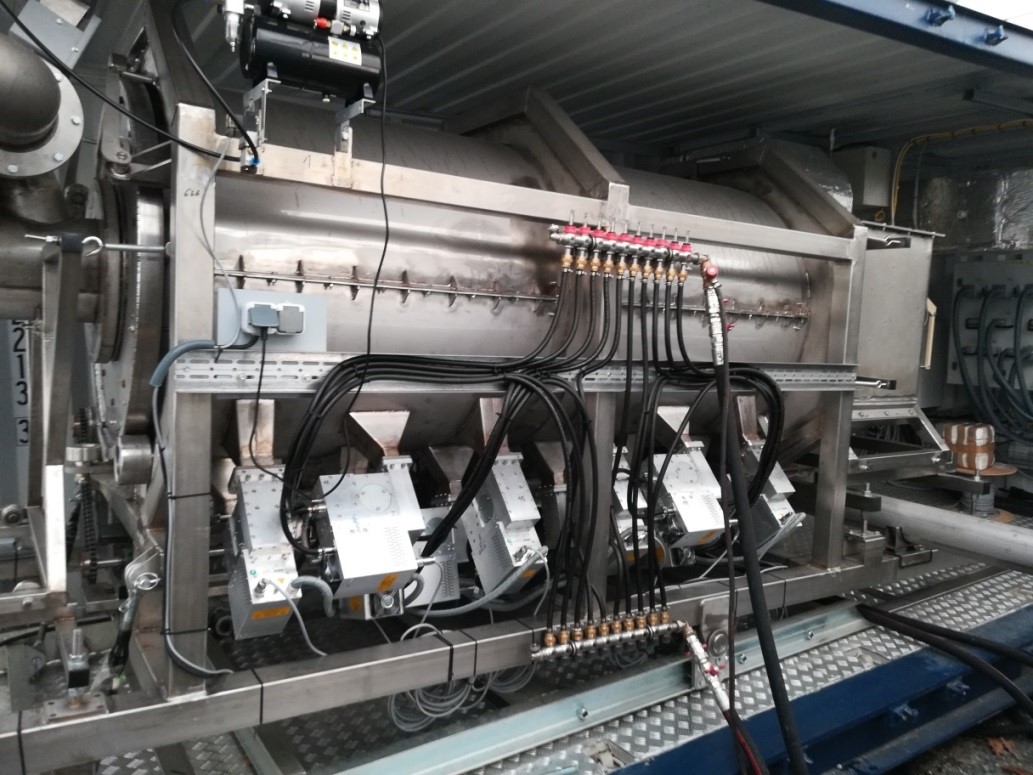

Technological line

The developed technological line comprises several devices distributed in six containers in the following configuration.

HR device

The HR reactor thermally treats the waste. The gases emitted during the process are passed directly to the MOS reactor, where they are correctly burned up and cleaned. The end product of this process is a small amount of char/ash with recoverable metallic materials (e.g. hospital sharps) deposited in a collection bin.

- Waste minimisation – a post-process product (weight and volume reduction),

- Cost saving for the operational cost to heat the waste material in its entire volume directly by not requiring additional fossil fuel as an ignition catalyst. Production of profitable excess energy, either heat or electricity, for use or sale.

- No emitted odours all fragrances are oxidised in the MOS segment.

- Transportable – the possibility of transporting devices to the place of waste.Safely used in controlled environments like hospitals.

- “Zero” CO2e emission to the environment – no additional fuel stoichiometric (where all available oxygen is completely consumed) emission from the material; Zero production of Dioxins & Furans using ATON’s accurate temperature controls.

MOS device

The purification of gases using the MOS technology described above is carried out in MOS reactors. They are structurally simple devices for afterburning pollutants in waste gases from industrial installations. The reactor’s purpose is to burn up organic compounds (hydrocarbons) and other volatile chemicals emitted during typical combustion processes.

The ceramic material placed inside the MOS reactor chamber is heated with microwaves to approximately a temperature. 1000⁰C, and the treated post-process gases, during turbulent flow through this ceramic bed, are heated to high temperatures in an oxidising environment. The highly heated ceramics also have an additional catalysing effect on the oxidation process.